|

|

| |

|

| Integrate a nitrogen generator in our production was an excellent idea! |

| …says Elie Jalbout – Head of production at Technica International s.a.l. The Lebanese company is investing in more sustainable production for sheet metal cutting. Its laser cutting machines are now supplied with an in-house production of nitrogen using an N2 generator. |

|

| |

|

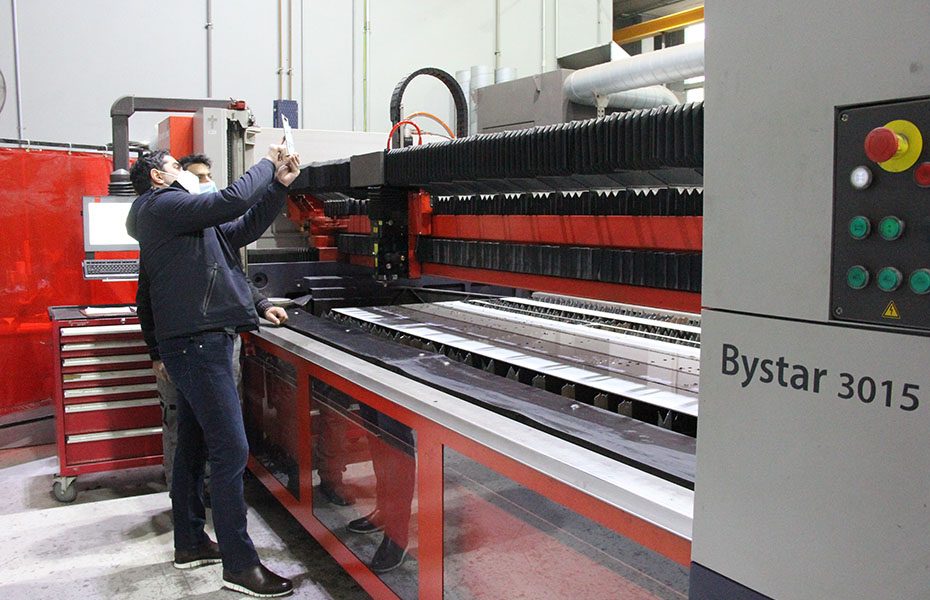

| High-end quality parts are cut using the powerful Bystar 3015, 4400W |

| One of the main reasons for this investment was to provide an independency for Technica to produce its own nitrogen without relying on suppliers. Thanks to the high purity level of 5.0 (i.e., quality 99.999) provided by the Airco Nitrogen generator PSAL 75 S, a nice side effect was that the laser cutting quality radically improved for all types of sheet metal. Another reason is the current unstable situation in the country. So suddenly, Technica is completely autonomous: “We no longer have to wait for trucks to deliver nitrogen, which then has to be converted into gas. Additionally, we only generate as much nitrogen as we actually need, and all the additional costs that were previously incurred (rental fee for the nitrogen tank, vehicle toll for the transport, and remote monitoring) are eliminated”, says Elie Jalbout. |

|

| Elie Jalbout , Head of Production: “We consider Bystronic as a partner with whom we built a strong relationship”

|

According to him, generating your own nitrogen not only makes sense, it also reflects the spirit of the times. Technica already installed solar panels on the roof of their factory so one of the ideas is, thus, generate zero carbon nitrogen in future.

“We are also proud that we were one of the first companies to integrate and operate an Airco system in the in region”, says Elie.

The phone rings. Before Elie answers the call from production people, he adds that Bystronic showed a high level of professionalism in managing the project from all aspects: Starting from the offer preparation and negotiation phase, to the shipping and installation (on time) and ending with the aftersales and services.

|

Good to know: Nitrogen as a cutting gas

|

| In laser cutting, cutting gas is used to ensure that both the laser and the metal sheet always remain free of contamination. Nitrogen is used for what is known as fusion cutting, while oxygen is used for flame cutting. Nitrogen offers a major advantage: It eliminates oxidation and thus improves the surface quality. |

|

| Technica is now producing Nitrogen with 99.999% purity in-house to ensure high quality cuts and so finishes with lower cost. |

| |

| More about Technica International s.a.l and its partnership with Bystronic |

Technica’s success story began in the deep green mountains of Bikfaya north of Beirut. Between tall pine trees and small villages lies the company headquarters. High above the Mediterranean, the shining white factory is literally stuck to the mountainside. Seven years ago, they looked for a modern cutting technology and found Bystronic. A few months later, the showpiece of the machine park – an 11.000-kilogram Bystar 3015 – arrived in their factory. The 4.4-kilowatt laser is burning through a thin metal plate to produce individual components for the highly complex production lines that make up Technica's core business. But the cutting gases is expensive and caused too many problems, so they invest in a N2 generator in 2021.

Very proud is Technica of its "AmbuVent": A ventilator that his employees developed within a very short time in response to the corona crisis and which out of its core business.

The parts are cut on the Bystar laser cutting machine. The machine, that is intended to start saving lives, is smaller than a moving box: a case made of stainless steel and glass containing a bag bellows that looks like a beating heart.

Technica sells and operates its tailor-made goods all over the world and its customers include global players. Technica is currently expanding its business in Poland and Canada to serve its European and American customers.

“Over the years our factory has transformed from a small-scale manufacturing to a modern industrial plant. Laser cutting, laser welding, CNC machines and 3D designing were introduced in our production divisions, and we also keep a pace on digitalization to enhance our production planning capabilities”, resumes Elie Jalbout.

|

| |

|

| Technica’s headquarter based at the heart of Bikfaya mountains get dressed in white during winter. |

| |

|

| Technica’s core business lies in automation solutions for different industries, such as F&B, home and personal care, logistics and others. |

| |

| |

| Profile Technica |

Fields of business: innovative, customized, high quality automation solutions & turnkey lines

Founded: 1982

Employees: 206

Revenue (2018): EUR 20 million

Production area: 6,000 square meters

Headquarters: Bikfaya, Lebanon

Bystronic customer since: 2016 |

| |

| |

| |

| All rights reserved 2022 |